Module 4 – Securing Windows & Other Openings

Chapter 12: Boarding

Although not the preferred method of securing windows, doors and other openings, boarding can be a viable option depending upon the broker’s sale plan, the client expectations and the characteristics of the surrounding community. When bidding and completing bolt boarding or boarding with wood screws, you must provide the following information to your client: exact measurements, total number of broken windows and their location (Basement, 1st floor, 2nd floor).

Example:

4- 48” x 32” located on 1st floor

1-60” x 42” located on second floor (oversized)

The method of boarding in most cases should be bolt boarding. The only exception is when bolt boarding will cause more damage to the home. Nails are never acceptable when securing a board over an opening.

Plywood should be used when completing any boarding service. Use of other materials such as OSB (Oriented Strand Board) or MDF (Micro Density Fiberboard) are not acceptable.

Boarding Installation Tools

- Tape measure

- Straight edge

- Square

- Carpenter pencil

- Drill

- Circular saw

- Carriage bolts, washers and nuts

- Drill bits, 5/8 inch drill bit for ½ inch carriage bolts, 1.25 inch paddle bit

- Plywood ½ inch CDX for windows, ¾ inch CDX for security doors (other wood types including OSB and MDF are not acceptable)

- 2×4 lumber

- Adjustable wrench – to tighten bolts

- Wood screws, 1.5 inch to 2.5 inches

- Hinges

- Padlock and hasps for security doors

Remember that most properties serviced will not have power, so cordless power tools will be needed and a generator should be available.

Boarding Measurement

When measuring windows and other openings for boarding, one should measure both the length and width of the entire opening.

This measurement should be provided to clients in in both square inches as well as United Inches (UI).

- To calculate square inches use the following formula:

- L x W = Square Inches

- To calculate United Inches use the following formula:

- L + W = United Inches

Bolt Boarding

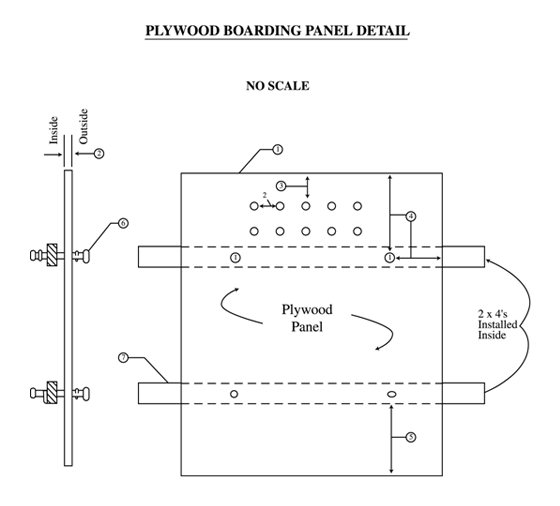

Cut one board to fit the entire opening (not just the broken pane of glass). The only exception will be windows that exceed 48”x 96” requiring multiple sheets of plywood. Drill holes in the plywood so that carriage bolts can be extended through the broken opening and through a 2×4, which will extend across the inside of the window. Tighten down the carriage bolts and sandwich the broken window in the middle. Bolts should be cut to approximately 1/2” past the nuts to eliminate the potential safety hazard of protruding bolts.

The following diagram is from HUD Mortgagee Letter 2002-10 Attachment 4. It provides a good illustration of the process of bolt boarding. It is critical for contractors to know the specific requirements of their geographical locations. Always refer to the local, state and HUD regulations for requirements on vent holes (shown below), light slots, priming and painting requirements, etc. These requirements vary from location to location.

*Courtesy of HUD Mortgagee Letter 2002-10 Attachment 4

Before Boarding

After Boarding Exterior

After Boarding Interior

Screw Boarding

Although not preferred, windows with wooden windows may be secured with screws in cases where reglazing, replacement or bolt boarding is not possible. To screw board a property, cut the plywood to size with no overhang. Install the board using 1.5 to 2.5 inch decking screws spaced a maximum of 4 inches apart. The board should not be able to be pried from the exterior after installation.

Overhead Garage Doors Procedure (Large Openings)

Bids to board large openings, such as overhead garage doors, should state that the opening must be framed and center joisted. 2×4 boards will be required for creating the frame and a center joist for securing the sheets of plywood. In situations where detached garages have no other entry point besides the garage door, a plywood security door with padlock and hasp should be included within the framework built to board the overhead opening thus preserving access to the structure.

In any case involving the boarding of an overhead door, bids should also be provided to replace the missing or damaged door as an alternative.

Plywood Security Door

The need for a plywood security door arises for two main reasons: 1) the door is missing or severely damaged and cannot function as a door, or 2) a local ordinance may require the installation of a security door, especially with regard to homes where the municipality has already boarded, or vacant homes where drug activities once occurred at the premises. When placing a bid for a security door, a bid should also be provided to replace the door as an alternative.

Plywood cut to the correct size is attached to the home with three hinges on one side and secured with a padlock and hasp on the other side covering the door opening. If the molding on the outside of the door being secured is not wide enough to secure the hinges, a block of wood must be installed to raise the hinge placement to allow the door (plywood) to close flat against the opening. Be sure to check with the client for their requirements on the number of hinges and padlocks/hasps to be used. Some clients require two padlocks/hasps on the new security door while others only require one.

Before

After